Introduction to Mithila Paints

Mithila Paints stands as a beacon of quality and innovation in the paint and coatings industry. Established decades ago, the company has built a solid reputation for delivering top-tier products that cater to both professionals and DIY enthusiasts. Their unwavering commitment to excellence is reflected in every product they manufacture, earning them the trust and loyalty of countless customers.

The history of Mithila Paints is one marked by a relentless pursuit of perfection. From its humble beginnings, the company has grown into a major player in the industry, thanks to its dedication to using only the finest materials and employing state-of-the-art technologies in their production processes. This ensures that every can of paint that leaves their facility is of the highest quality, capable of transforming spaces with ease and durability.

At the heart of Mithila Paints lies a set of core values that drives their mission. Innovation is a key pillar, as the company continually invests in research and development to introduce new and improved products that meet the evolving demands of the market. Quality is another cornerstone, with stringent quality control measures in place to ensure consistency and reliability in every batch of stucco texture they produce.

Mithila Paints is also deeply committed to sustainability and environmentally friendly practices. They prioritize eco-friendly formulations and strive to reduce their carbon footprint through various green initiatives. This responsible approach not only benefits the environment but also assures customers that they are choosing products that are safe and sustainable.

The trust bestowed upon Mithila Paints by professionals and DIY enthusiasts alike stems from their proven track record of delivering exceptional results. Whether it’s a simple home makeover or a large-scale commercial project, their stucco textures and other paint products are designed to meet the highest standards, ensuring lasting beauty and protection for any surface.

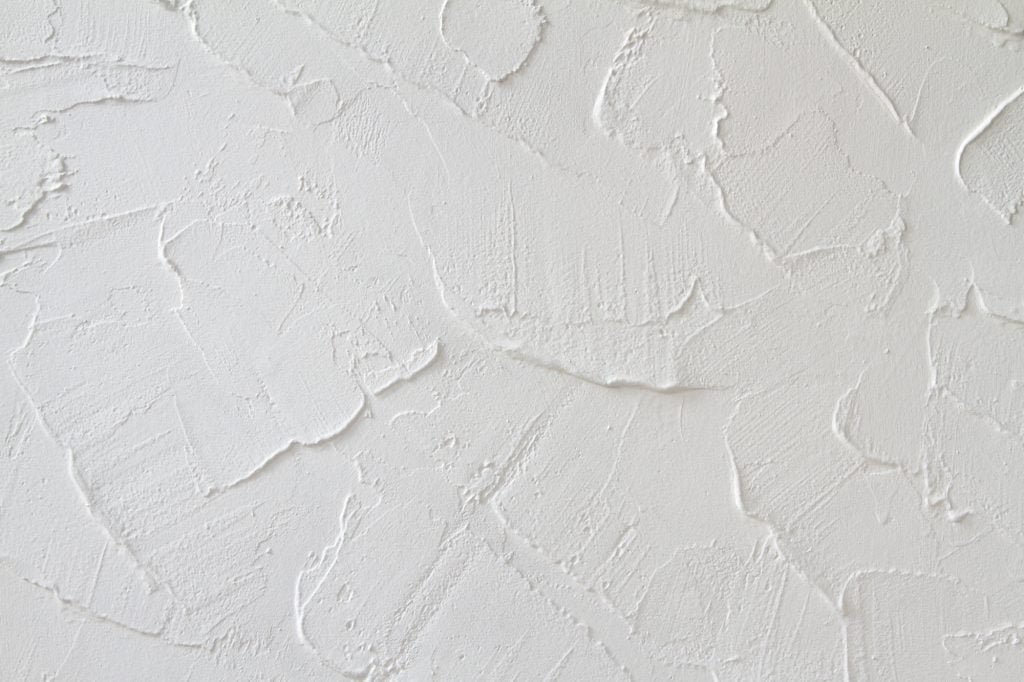

Understanding Stucco Texture

Stucco texture refers to the surface finish achieved using a cement-based plaster commonly applied to exterior and, sometimes, interior walls. Its origins date back to ancient Greece and Rome, where it was utilized not only for its practical benefits but also for its decorative appeal. Over the centuries, stucco has evolved, incorporating modern techniques and materials to meet contemporary architectural needs while retaining its timeless charm.

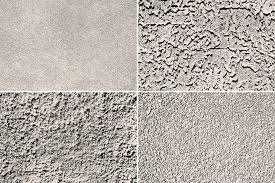

Diverse types of stucco finishes cater to varying aesthetic preferences and functional requirements. Smooth finishes, for instance, exude a sleek and modern appeal, ideal for minimalist architecture. On the other hand, rough textures, such as dash or pebble-dash, add a distinctive character to buildings, showcasing a more rustic or traditional look. Sand finishes incorporate fine aggregates to produce a subtler, granular surface, while patterned textures involve customized designs, enabling endless creative expression.

The use of stucco in modern architecture is widespread due to its numerous benefits. First and foremost, stucco is celebrated for its remarkable durability, capable of withstanding extreme weather conditions without compromising structural integrity. Its inherent weather resistance makes it particularly suitable for regions prone to harsh climates, offering excellent protection against moisture, wind, and temperature fluctuations.

Aesthetic appeal is another significant advantage of stucco texture. Its versatile nature allows homeowners and architects to tailor finishes to desired stylistic outcomes, whether they seek a classic, contemporary, or avant-garde look. Moreover, stucco can be tinted with various colors, adding vibrancy and character to any construction.

In conclusion, understanding the nuances of stucco texture—from its rich historical roots to its modern applications—unveils a world of possibilities for enhancing architectural appeal and functionality. Diverse finishes and numerous advantages make stucco a preferred choice in contemporary building designs, seamlessly blending tradition with innovation.

Materials and Tools Required

When embarking on a stucco texture project, the first critical step is gathering the necessary materials and tools. Using high-quality supplies ensures that the final outcome is durable and aesthetically pleasing. This guide will cover the essential items, with a special focus on recommended products from Mithila Paints.

The foundational material for stucco texture is the base mix, typically composed of cement, sand, and lime. For optimal results, consider using Mithila’s pre-mixed stucco base, which offers consistent quality and ease of application. This ready-to-use base mix saves time and guarantees a uniform texture across the entire surface.

Pigments are crucial to adding color and depth to your stucco finish. Mithila Paints offers a wide range of high-quality pigments that are specifically designed for use with stucco. Their pigments are fade-resistant and provide vibrant shades that enhance the overall appearance of your project. Ensure the chosen pigments are compatible with your base mix to avoid any issues during application.

Sealers play a vital role in protecting the stucco surface from moisture, weathering, and other environmental factors. Mithila’s durable sealers are recommended as they offer excellent protection while maintaining the texture’s integrity. Applying a good sealer extends the life of your stucco and keeps it looking fresh for years.

For the application process, you’ll need a set of specialized tools. Basic tools include a trowel, hawk, and a float. Mithila Paints offers a premium set of stainless steel trowels and floats designed for precise and smooth application. Additionally, consider using brushes and sprayers for more intricate textures and finishes. A high-quality sprayer can provide an even coat and help achieve complex textures effortlessly. Ensure all tools are cleaned thoroughly after use to maintain their performance.

Finally, don’t overlook safety gear. Gloves, safety goggles, and masks are essential to protect yourself from dust and chemicals during the application process. Investing in high-quality materials and tools from reputable suppliers like Mithila Paints is key to mastering the art of stucco texture and achieving professional results.

Surface Preparation

Achieving a durable and aesthetically pleasing stucco texture requires meticulous surface preparation, a critical step in the stucco application process. The initial phase involves cleaning the surface to eliminate any dust, debris, or grease, which could interfere with the bonding of the stucco to the substrate. For cement surfaces, pressure washing is an effective method to ensure a clean and smooth base. For wooden substrates, sanding is essential to create a slightly roughened texture, promoting better adhesion.

Addressing any damage or imperfections on the surface is pivotal before moving forward. Cracks, holes, and other defects should be repaired using appropriate fillers. Cement-based patching compounds work well for concrete and brick surfaces, while wood filler is suitable for wooden substrates. Ensuring a flawless foundation helps in avoiding future deterioration and contributes to the stucco’s longevity.

Once the surface is clean and repaired, the next step is to apply a bonding agent, which enhances the adhesion between the substrate and the stucco layer. For concrete surfaces, a concrete bonding adhesive ensures a strong bond. On wooden surfaces, a primer that’s designed for adhering stucco to wood should be used. Brick surfaces benefit from a masonry bonding agent to achieve similar results.

Different types of surfaces require tailored approaches to preparation. Cement and concrete substrates demand thorough cleaning and occasional acid etching if they’re particularly smooth. Wood must be moisture-free and sealed with an appropriate primer. Brick surfaces, often porous, should be scrubbed and then rinsed with water to remove any loose particles.

Thorough surface preparation is vital for achieving an enduring and visually stunning stucco texture. It ensures proper adhesion, prevents future peeling and cracking, and ultimately contributes to the overall resilience and beauty of the finished surface. Proper preparation lays the groundwork for a successful application, a step too crucial to be overlooked in the pursuit of stucco perfection.

Mixing Mithila’s Stucco Products

The process of mixing Mithila’s stucco products is a crucial step in achieving the perfect texture and finish. Ensuring accurate measurements, adhering to recommended mixing techniques, and obtaining the desired consistency are all pivotal. Following Mithila’s comprehensive guidelines helps to streamline this process and guarantees optimal results.

Begin by preparing your work area, ensuring it is clean and free from dust or debris. Use a clean mixing container and always measure the materials precisely. For Mithila’s pre-mixed stucco, combine one part water to five parts stucco powder by volume. Adjustments may be necessary based on the specific product line, so always refer to the product instructions for precise ratios. Using a calibrated measuring device ensures accuracy, which is essential for consistent results.

Once you have your materials prepared, start by adding the water into the mixing container. Gradually incorporate the stucco powder into the water, rather than adding water to the powder. This technique minimizes clumping and ensures a smooth mixture. Use a mechanical mixer on low speed to blend the materials thoroughly. Mixing by hand can be viable for smaller batches, but for larger quantities, mechanical mixing is recommended to achieve uniformity.

Aim for a consistency that is smooth yet firm enough to hold shape when applied to surfaces. Avoid making the mix too watery, as this can weaken the final finish and cause poor adhesion. On the contrary, if the mix is too thick, it will be challenging to spread and may not adhere properly. The ideal texture should be similar to creamy peanut butter or a thick pancake batter, providing both workability and durability.

Bear in mind that coloring agents should be added during the mixing phase if you are aiming for tinted stucco. Mithila’s color additives are designed to blend seamlessly with their stucco products, creating a consistent and vibrant hue. Mix the colorant thoroughly into the stucco to avoid streaks or uneven coloration.

Following Mithila’s specifications reduces the likelihood of errors and enhances the final outcome. Their user-friendly products and detailed guidelines simplify the mixing process, allowing both amateur and professional applicators to achieve exceptional results with ease.

Application Techniques

Applying stucco texture effectively requires expertise in various techniques, each capable of producing different aesthetic results. Mastery in these application methods ensures a uniform finish, durability, and overall appeal. Below, we explore hand troweling, spraying, and brushing techniques, complete with detailed steps to achieve both smooth finishes and intricate patterns.

Hand troweling is a traditional technique that involves using a trowel to spread the stucco mixture onto the surface. Start by applying a base layer uniformly, ensuring there are no gaps. With the trowel at a consistent angle, move it in sweeping motions to flatten the stucco evenly. For a smooth finish, lightly mist the surface with water and pass the trowel again to compress the material. Patience and steady hands are crucial to avoid streaks and uneven textures. It’s essential to let the first layer cure adequately before adding more layers to enhance the texture.

Spraying stucco speeds up the application process, particularly for larger areas. Using a stucco sprayer, load the mixture and apply it by moving the spray gun in consistent, even passes. Spray from a distance of around three feet to distribute the stucco evenly. To achieve varied textures, adjust the nozzle settings. For a smooth finish, follow up with a trowel or float. Remember to ensure adequate curing time between each layer to prevent cracking.

Brushing techniques offer unique, textured finishes that stand out. After applying the base coat with a trowel or sprayer, use a stiff-bristled brush to create patterns. Whether you prefer swirls, crisscrosses, or linear designs, the brushing technique allows for creative freedom. Lightly press the brush into the semi-wet stucco and move it according to your desired pattern. Repeat as necessary, ensuring even coverage. It’s vital to keep the stucco moist during this process to facilitate ease of manipulation.

Common mistakes in stucco applications include not allowing sufficient curing time, overloading the trowel, and inconsistent application. To avoid these, always respect the material’s drying time between layers, apply thin, even coats, and ensure consistent pressure during application. Regularly check for uniformity in texture to preemptively correct any deformities.

Layering is fundamental to achieving the desired stucco finish. Begin with a scratch coat, let it cure, then apply the brown coat, allowing sufficient time for each to dry. The final coat can be textured as required. Proper curing prevents cracking and ensures long-lasting durability.

Finishing Touches

Upon completing the primary application of the stucco, attention must turn to the finishing touches that ensure a polished and durable surface. The first step in this phase is smoothing. Using a high-quality trowel, gently smooth the surface while it is still slightly damp to eliminate any unwanted ridges or inconsistencies. Consistency in pressure and motion is crucial to achieving a uniform texture.

Once smoothing is completed, the next focus is on texturing. Texturing can be achieved through various techniques such as scraping, swirling, or even stamping, depending on the desired aesthetic. It is advisable to experiment with different methods on a small surface area before committing to a larger section. The critical point here is to prevent the stucco from drying out; periodically mist the surface with water to maintain workability.

Sealants or protective coatings play a pivotal role in the longevity and appearance of the stucco finish. Mithila Paints offers a variety of sealants that not only protect the surface from moisture and environmental damage but also enhance the color vibrancy. Applying the sealant evenly with a brush or roller, ensuring complete coverage without over-application, will help to create a resilient barrier.

For those seeking to add a touch of character, optional steps such as adding color or decorative elements can truly set the stucco apart. Mithila Paints provides a wide array of pigments and decorative finishes that can be integrated into the sealant itself or applied as a final layer. Whether opting for a subtle hue or an elaborate design, these additions should be planned meticulously to ensure uniformity and integration with the overall aesthetic.

By following these steps, one can transform a basic stucco application into a sophisticated and enduring finish. The key lies in the careful execution of each step, utilizing the specialized products from Mithila Paints to achieve the desired outcome.

Maintaining stucco surfaces properly ensures their longevity and keeps them looking their best. Regular care involves simple, yet effective, cleaning methods, routine inspections, and timely repairs. When it comes to cleaning, a gentle wash using mild detergent and water can effectively remove dust, dirt, and mildew. Avoid using abrasive tools or high-pressure washers, as they can damage the stucco’s surface. For more stubborn stains, a soft brush and a specialty stucco cleaner can be employed.

Routine inspections are crucial to identifying early signs of wear and tear, such as cracks or chips. Conduct a thorough inspection at least twice a year, typically in the spring and fall, to assess the condition of the stucco. Pay close attention to areas around windows, doors, and joints, as these are more susceptible to damage. When cracks or blemishes are detected, it’s essential to address them promptly. Mithila Paints offers a range of repair products specially formulated for stucco surfaces. These products are designed not only to mend the damage but also to seamlessly blend with the existing texture and color.

Mithila Paints’ stucco products stand out for their durability and ease of maintenance. They are engineered to resist weathering, UV rays, and moisture, significantly reducing the frequency of repairs. To maintain their effectiveness, it’s recommended to follow a maintenance schedule. Alongside biannual inspections, reapplication of a high-quality stucco sealer every 3-5 years can provide an extra layer of protection, enhancing the surface’s resistance to environmental factors.

In addition to regular inspections and cleaning, ensure proper drainage around the stucco surface to prevent water accumulation, which can lead to serious damage over time. By adhering to these maintenance strategies and leveraging the superior qualities of Mithila Paints’ products, you can effectively preserve the integrity and beauty of your stucco finishes, ensuring they remain a lasting feature of your property.